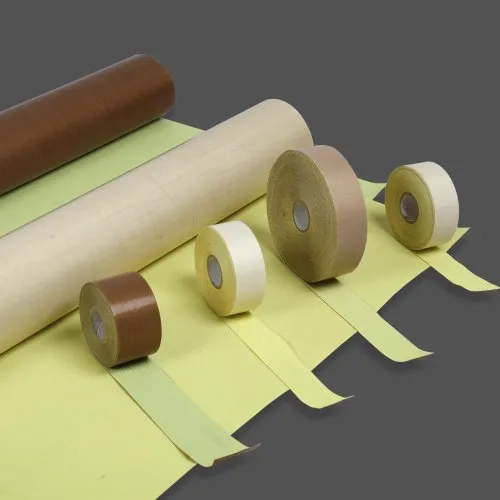

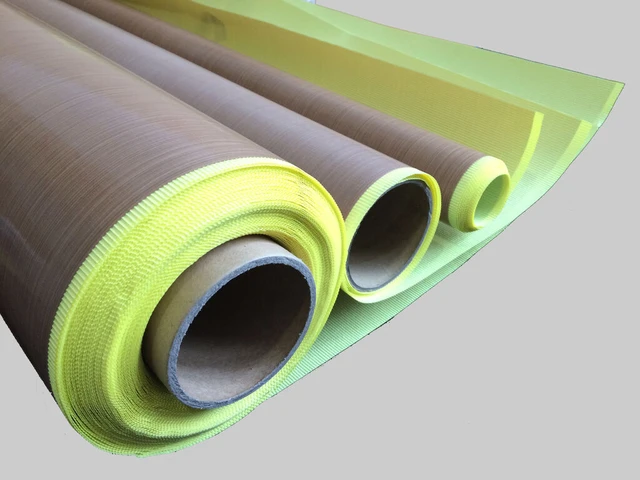

PTFE Fiberglass Adhesive Tape

Discover the strength, versatility, and reliability of our PTFE Fiberglass Adhesive Tape, engineered to meet the most demanding industrial requirements. This tape combines the excellent properties of PolyTetraFluoroEthylene (PTFE) with the mechanical strength of fiberglass, making it an ideal choice for a wide range of applications across various industries.

PTFE Fiberglass Adhesive Tape

Discover the strength, versatility, and reliability of our PTFE Fiberglass Adhesive Tape, engineered to meet the most demanding industrial requirements. This tape combines the excellent properties of PolyTetraFluoroEthylene (PTFE) with the mechanical strength of fiberglass, making it an ideal choice for a wide range of applications across various industries.

Key Features

Explore the unmatched benefits of our PTFE Fiberglass Adhesive Tape, designed to provide reliable, high-performance bonding solutions across various industrial applications. This tape excels in environments requiring durable adhesion, thermal stability, and chemical resistance, ensuring your operations maintain continuity and efficiency.

Temperature Resistance

Withstands a broad temperature range from -70°C to 260°C, ensuring performance stability in extreme heat or cold.

Non-Stick Surface

The smooth, PTFE-coated surface prevents materials from adhering to the tape, making it easy to clean and maintain.

Fire Retardant

Offers excellent fire resistance, enhancing safety in industrial settings.

Dimensional Stability and Strength

The fiberglass mesh provides high tensile strength and excellent dimensional stability under mechanical stress.

High Insulation

Ideal for applications requiring superior electrical insulation.

Anti-UV and Anti-Static Properties

Protects against ultraviolet radiation and static electrical charges.

Product Specifications

Thickness Options

Available in 0.08mm, 0.13mm, 0.18mm, 0.25mm, and 0.3mm, catering to a variety of application requirements.

Colors Available

Offered in brown, black, and white to suit different aesthetic and functional needs.

Release Liner

Available with or without a release liner, providing flexibility based on application needs.

Applications

Packaging

Ideal for heat sealing machines in the packaging industry, providing a durable, non-stick surface that withstands high temperatures.

Electrical

Used for insulation in electrical assemblies, protecting components from heat and providing an insulative barrier.

Manufacturing

Acts as a release surface on heat sealers, form-fill-seal equipment, and laminating equipment where a heat-resistant, non-stick surface is critical.

Aerospace and Automotive

Provides reliable insulation and protection in composite bonding and manufacturing processes.